Click on the slideshow picture (right) for a printable copy

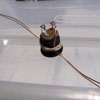

E248 Jack and Plug

cutting grooves with a dremel burr so the wires can come to the outside

CustomJack01D.jpg

cutting grooves with a dremel burr so the wires can come to the outside

CustomJack01D.jpg

This is where the tapewire is most often routed for a Surface Junction connection

IMG_5563D.jpg

This is where the tapewire is most often routed for a Surface Junction connection

IMG_5563D.jpg

heat softens glue but don't let the paint get so hot you can't lay your hand on it

IMG_5573D.jpg

heat softens glue but don't let the paint get so hot you can't lay your hand on it

IMG_5573D.jpg

drill just past the tapewire and a 5/8" on center below the bottom of the wall

IMG_5586D.jpg

drill just past the tapewire and a 5/8" on center below the bottom of the wall

IMG_5586D.jpg

Glue in the Jack - use lots of glue spread all the way around to grab the threads

IMG_5587D.jpg

Glue in the Jack - use lots of glue spread all the way around to grab the threads

IMG_5587D.jpg

This slideshow uses a 248 Jack mounted with all the wiring on the outside to replace a Surface Junction with minimum disruption of a finished house. This isn't the preferred use of a Jack and Plug, but it is an option when there's no access to the underside or to avoid working inside the house.

for under-the-house wiring