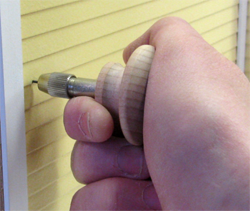

EL66 punch:

push, hammer, or drill a perfect hole for starting a small screw

Hinges and Screws

Punch starter holes

Flat Hinges line themselves up with the edge of the panel by folding them across the edge. If the screw-holes are started perfectly centered in the hinge-hole, the hinge will be straight when the process is done. I take extra care to get the holes started right in the center of the hinge-hole (a word of caution, the starter-hole has to go almost all the way thru the panel, and, eyes and judgement being a variable quantity, sometimes I drive the nail all the way thru the panel and into the table underneath. If I’m in the kitchen or dining room, a left over magazine under the panel protects the counter from becoming a permanent reminder of my shortcomings).

Ream the holes

The tip of an X-acto knife twirled in the starter hole gives a nifty taper to the hole. That makes the screw loose at the top (handy for getting it to stand up when the screw is just starting) but still lets it grip on the bottom, which is where the strength of a screw comes from anyway. That also gives a space for the tapered part of the screwhead that sticks down below the hinge material. If there’s no place for that tapered part, the screw will not tighten down the last little bit. When using a knife to taper the hole, use lots of twirl and not much down-pressure. The tip of an X-acto is fragile, and I’ve twirled off the tip by pushing down too hard.

Fitting the Screwdriver to the screw

The screwdriver has to really fit the screw. The smallest dollhouse screws are sized for a #0 screwdriver, but my utility drawer tool is a #2 – perfect for stripping the slots out of the screws but not for much else on a dollhouse. A trip to the hardware store with a screw in-hand will yield a new screwdriver that fits so well the screw will stay on the tip when you hold the screwdriver horizontally. That’s one that fits and is sharp. If you wonder if your screwdriver fits and is sharp, do this test.

Make it easy

If the hole is too tight or the wood too dry, the screw won’t turn in easily. I aim for a gentle-fit in the hole, and I use a spot of glue for lubrication. This is particularly important with MDF which is very dry (but once the screw is in, it really holds the threads).

Don’t over-tighten

An extra turn for good measure just strips the wood so it’s not holding the screw any longer. Once the screw touches the hinge, it’s done.