Straighten during assembly: slideshow

Pre-Straighten a part: here

Sunshine and Grass

Damp Towel and Spacers - blog

Straighten with an Iron - slideshow

![]()

high adhesion masking tape

Packing tape

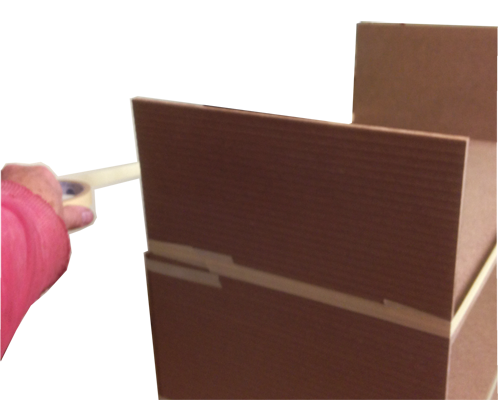

Pull tight

A well-taped corner

Wood changes shape as moisture changes, and moisture is changing all the time. Moving wood parts from one location to another, seasonal changes, moisture from paint, or just which side of the piece is face-up on the table: it’s part of the natural behavior of wood. It’s not much of a problem once a dollhouse is assembled and the parts are holding each-other in position. And it's not usually much trouble when building a dollhouse either... If a part can be pulled straight in assembly then it will stay straight down the road. When I build a house I expect to straighten every part a little bit, and to straighten some parts a lot… it is all part of the builder’s art.

For most parts, pulling them straight in assembly is easy when they line up at the corner with another part, and taping around the corner will both straighten the part and hold the glue joint tight while the glue dries. (see "Straighten a part during assembly" at left)

There are some parts, however, that don’t line up at a corner (like Dividers). Those parts are easiest to handle when they are pre-straightened for assembly. In the winter I usually get the straightening I need by turning the part over several hours before assembly. In the winter, parts become ‘belly-down’ when they are on the table, and turning them over puts the belly up where the air is dry, and the part reacts to that by going the other way. Putting weights on the part just interferes with the air getting to the piece and with the attempt to overcome unequal moisture, so it doesn't help in straightening a part and may even keep the "dry air" technique from working.

I have to be ready to use them when they are straight though, as they can go too far if left too long. (see "Damp Towel and Spacers" at left)

In the summer, I put the parts on the grass belly-up in the sunshine. Again, I have to be ready to use them when they are straight. ... (20 minutes or so is sometimes all it takes)

Trust your tape! Tape pulls with remarkable force when you use a fairly long piece and rub it down on one face, then pull until you can see the tape stretch and, holding the pull, rub it down on the other face. I sometimes use multiple layers of tape in a long strap when I want to pull very hard, and I pull a band of tape all the way around a house where I want a good pull and don’t have a convenient place to rub it down. Before I began building dollhouses, I had no idea how powerful a well-taped corner using masking tape really is, but now I use it with confidence.

So, give these techniques a try - it's what I do every day...

Try just pushing the part straight with your fingers; if you can and it's a 'corner' part, you will be successful building it straight without any other concerns.

Try turning it over for the night. If it moves at all, the "one side exposed" technique will make things easier.

Try the damp-towel or the grass-in-the-sunshine technique.

If it’s too stiff to be pushed straight and it doesn’t respond to sunshine on the grass and you MUST have it straight, try the "Straighten with an Iron" technique. It takes more fortitude and it should be left to last, but it is very effective (ask any boat-builder) and particularly so for MDF which relaxes its internal structure with heat.

If you replace parts, they will be subject to the same physics as the existing parts, and no selection of parts will eliminate the need for the builder to manage them when gluing.